Case Study:

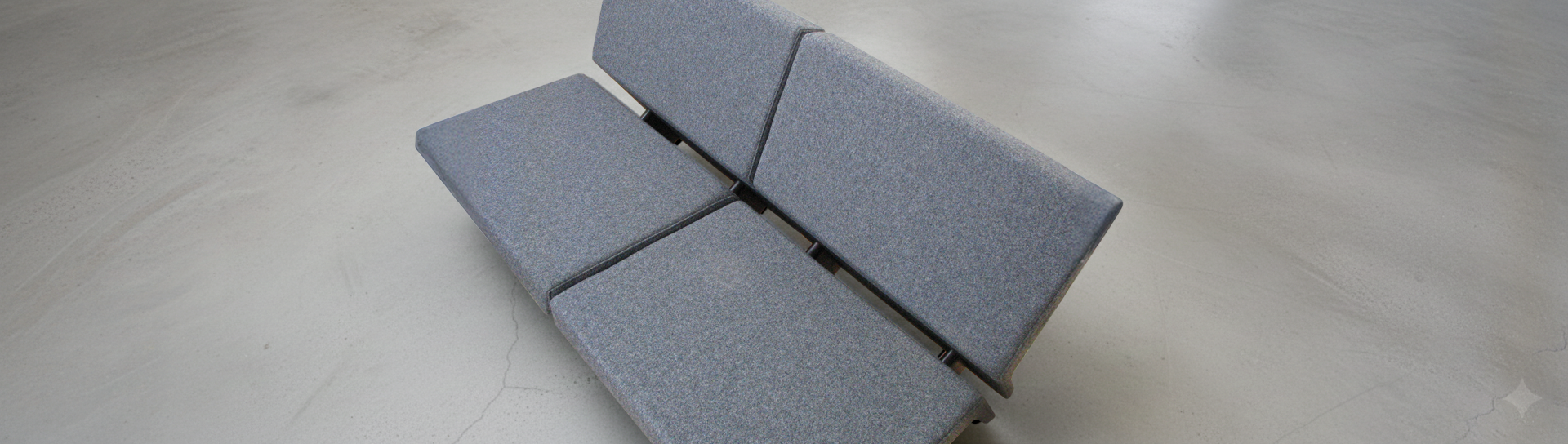

LR Lounge Chairs

-A study in material honesty and modular simplicity.

Materials & Systems

Overview:

These molded plywood lounge chairs were designed to bring warmth and refinement into modern interiors while staying true to principles of modularity and production efficiency. The design achieves a timeless silhouette that is as practical as it is beautiful.

Our Role

Concept Strategy / Industrial Design / CMF / Design for Manufacturing

Approach:

Timeless design grounded in practicality.

The design approach was to create a modern chair suited for contemporary interiors, while optimizing for modularity, flexibility, customization, and shipping. Mid-century influences inspired the molded plywood forms, while modern considerations drove material selection, and ease of assembly. The stainless steel base provides strength with minimal material, while molded plywood back panels can be exposed or fully upholstered to introduce warmth, texture, and tactile contrast.

Process:

From sketch to streamlined form.

The design evolved through iterative sketching, 3D CAD, and physical prototyping. Focus was placed on reducing the number of parts and, minimizing material waste, and simplifying assembly. The bent stainless steel base is made from a single rod formed on a CNC bender and held in place with profiled walnut trim pieces. Back and seat panels were molded from the same profile and designed as modular components, creating a layered aesthetic while allowing for customization or material variation. Even the upholstery technique was designed for easy customization and flexibility.

Result:

The LR lounge chair balances user comfort, modular design, and production intelligence. By combining honest materials with thoughtful detailing, it offers versatility across residential and hospitality settings. Lightweight to ship, simple to assemble, and elevated in presence, the chair demonstrates how industrial design can unite form, function, and feasibility.